SWIFT AUXI TECHNIK P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SWIFT AUXI TECHNIK P.LTD.

Access Loader

Access Loader

Cleaning and maintaining loaders is now faster, easier and safer than ever before.

All material contact surfaces are built of pristine steel or aluminum to prevent corrosion.

Cast aluminum based with protective stand - offs and integral discharge pan.

Full featured control platform govern all aspect of loader including load time material demand ratio and many other loading parameters.

Regenerative vacuum blower required no maintenance and no sound proofing.

Easy to load virgin and re-grind material simultaneously.

Powder Loader

Application

SWIFT POWDER LOADER (SPL) series separate - vacuum hopper loaders collocated with stainless steel hopper ensures no material contamination. The whole range comprises of seven models equipped with vacuum blower from 1 to 15HP.

SPL series separated - vacuum hopper loaders are based on the SPL and can be customized to equip with different filter powder hoppers, especially suitable for 30% and 100% powder loading.

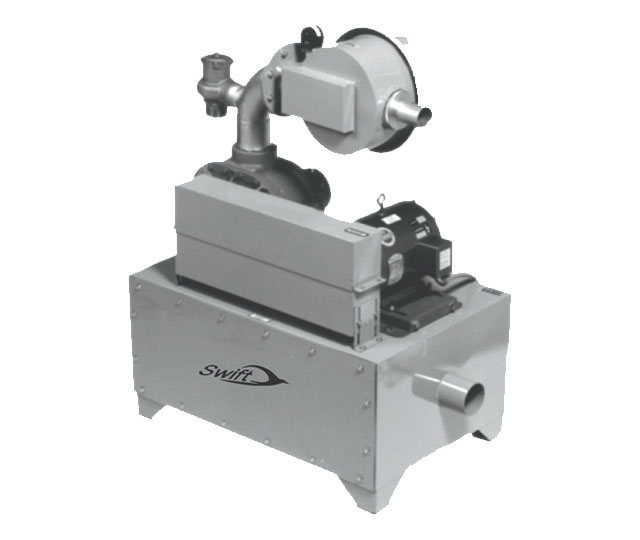

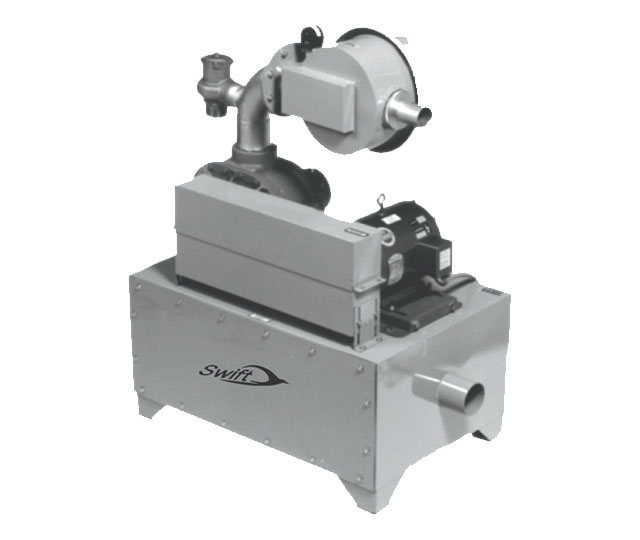

Positive Displacement Pumps

Unique Features

The most powerful vacuum source available.

14 square feet filter products pumps against damage from resin dust.

All service components are within easy reach.

Includes vibration pads, vacuum gauge, vacuum relief valve and magnetic starter.

Expect years of service with minimal attention.

Rotating lobe vacuum blower

Pump protection filter included

Easy maintenance

Ready to install

Powerful and reliable

Positive Displacement Vacuum Pumps are designed for long distance, high-volume material conveying.d est laborum.

Each model employs a powerful, rotating lobe-type blower, protected by a vacuum relief valve (factory-set to 12" Hg) and belt driven by a three-phase motor with magnetic starter and overload protection.

An integral pump protection filter is included. All components are mounted on a rugged frame that house an integral exhaust muffler.

An optional sound enclosure may be added to reduce noise.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

55501.jpg)